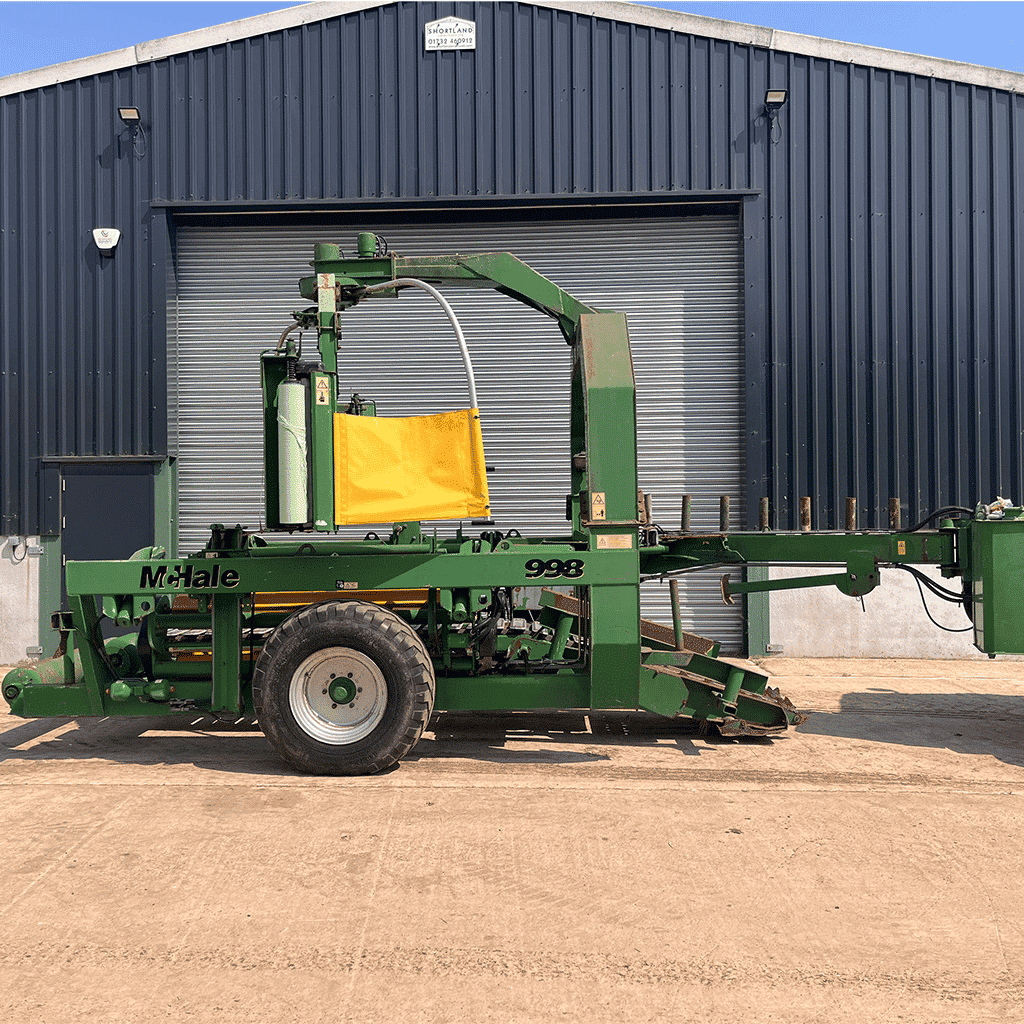

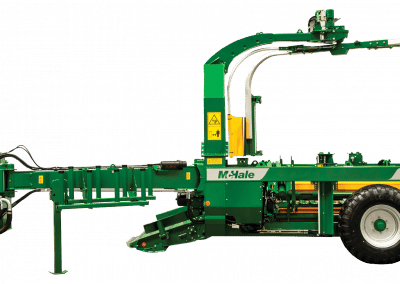

McHale 998 Square Bale Wrapper

998 Square Bale Wrapper

The McHale Square Bale Wrapper Range has been meticulously crafted with the demands of today’s farmer and contractor at the forefront. Consequently, this common-sense approach to design ensures that each machine’s operation is kept simple and user-friendly. Additionally, it delivers the highest output and reliability, achieved through the utilization of quality components, precision engineering, as well as our patented oscillating rollers and roller angle measuring system. Consequently designed to provide greater operator comfort and flexibility whilst maximising output and reducing maintenance intervals.

- Patented Oscillating Rollers – These cradle the bale during wrapping and steadily rotate the bale to ensure a uniform and correct overlap.

- Patented Roller Angles Measuring System – This ensure a consistent and even wrap regardless of square bale size or shape.

Built To Last

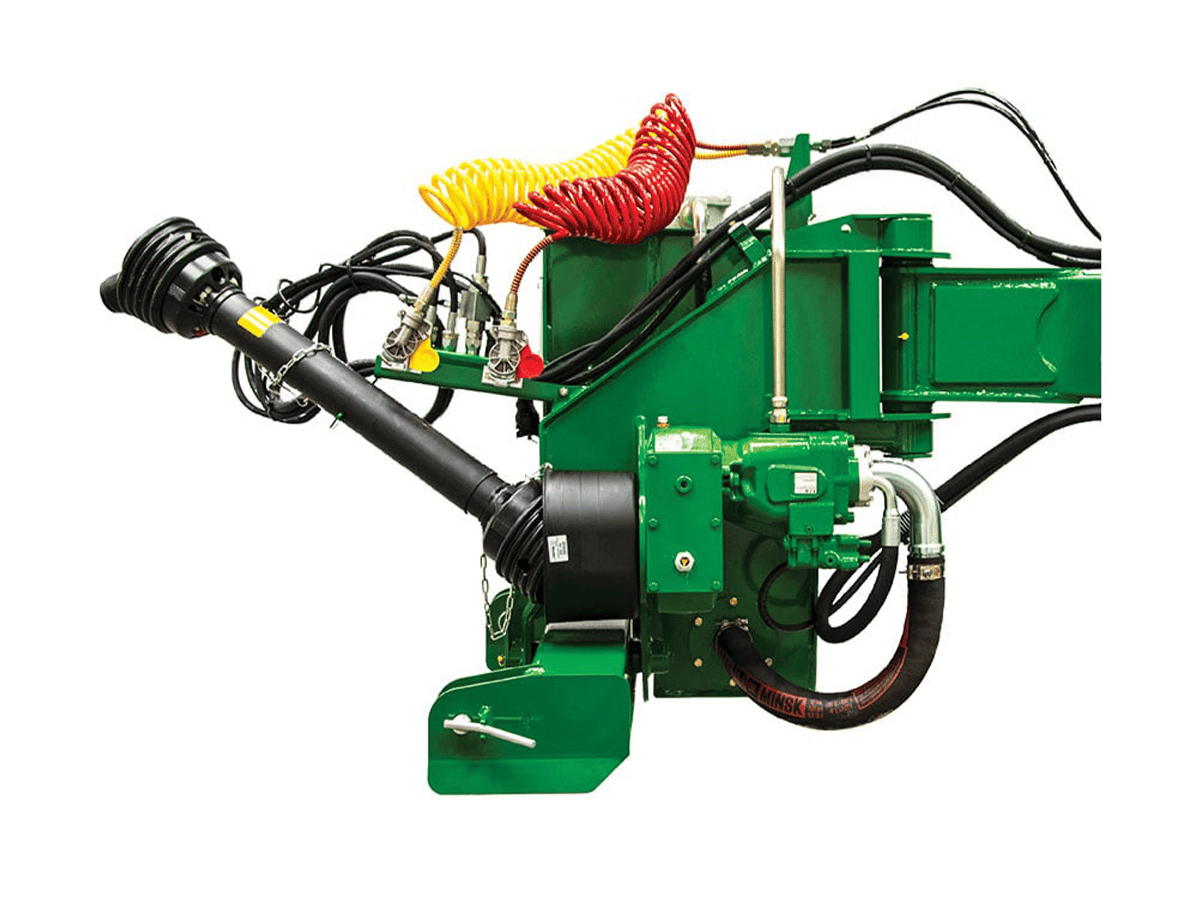

Independent Load Sensing Hydraulic System

Firstly the McHale 998 square bale wrapper is equipped with a fully integrated, PTO driven, load sensing hydraulic system allowing for a low horsepower requirement.

Subsequently this simplifies tractor change over and delivers consistent performance, eliminating problems associated with different tractor hydraulic systems, oil flows and oil temperatures. The stand-alone load sensing hydraulic system also reduces the risk of oil contamination.

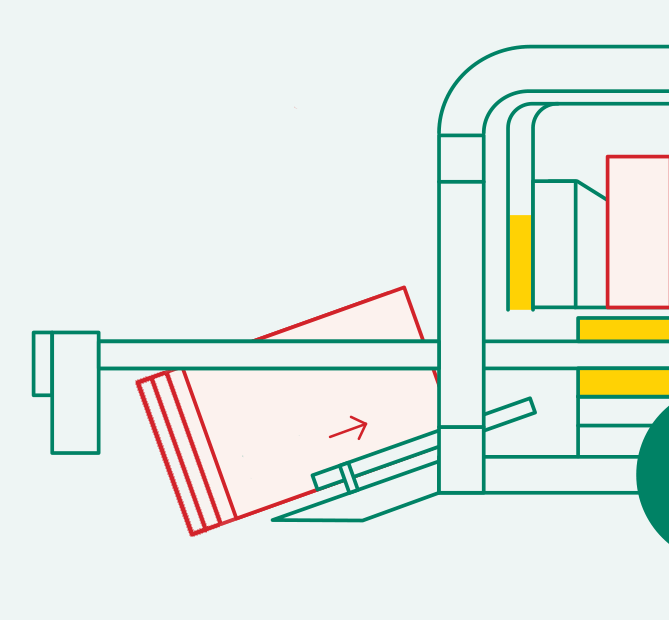

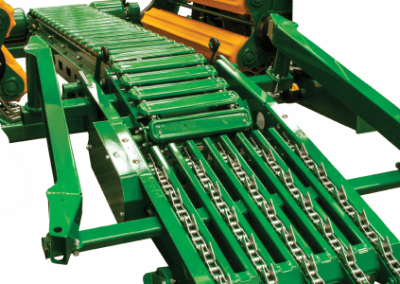

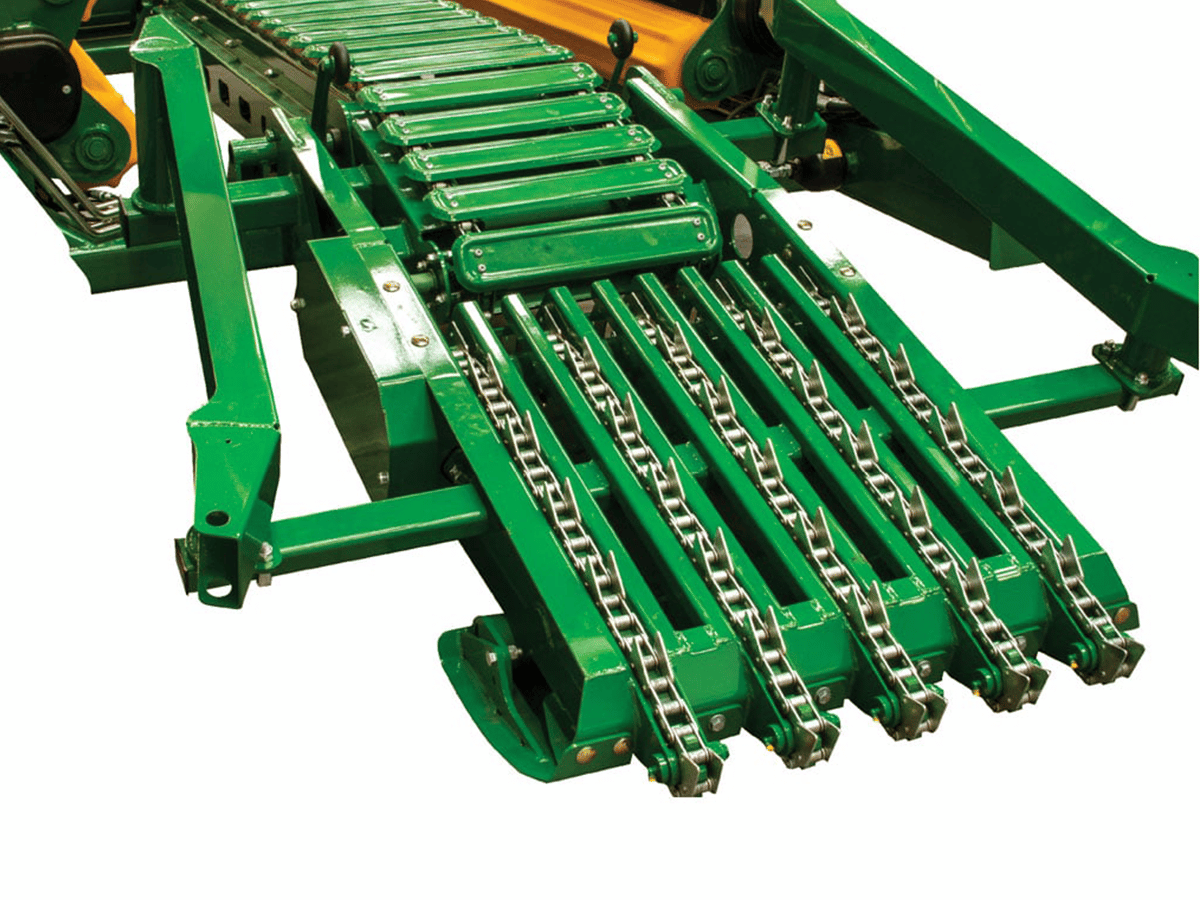

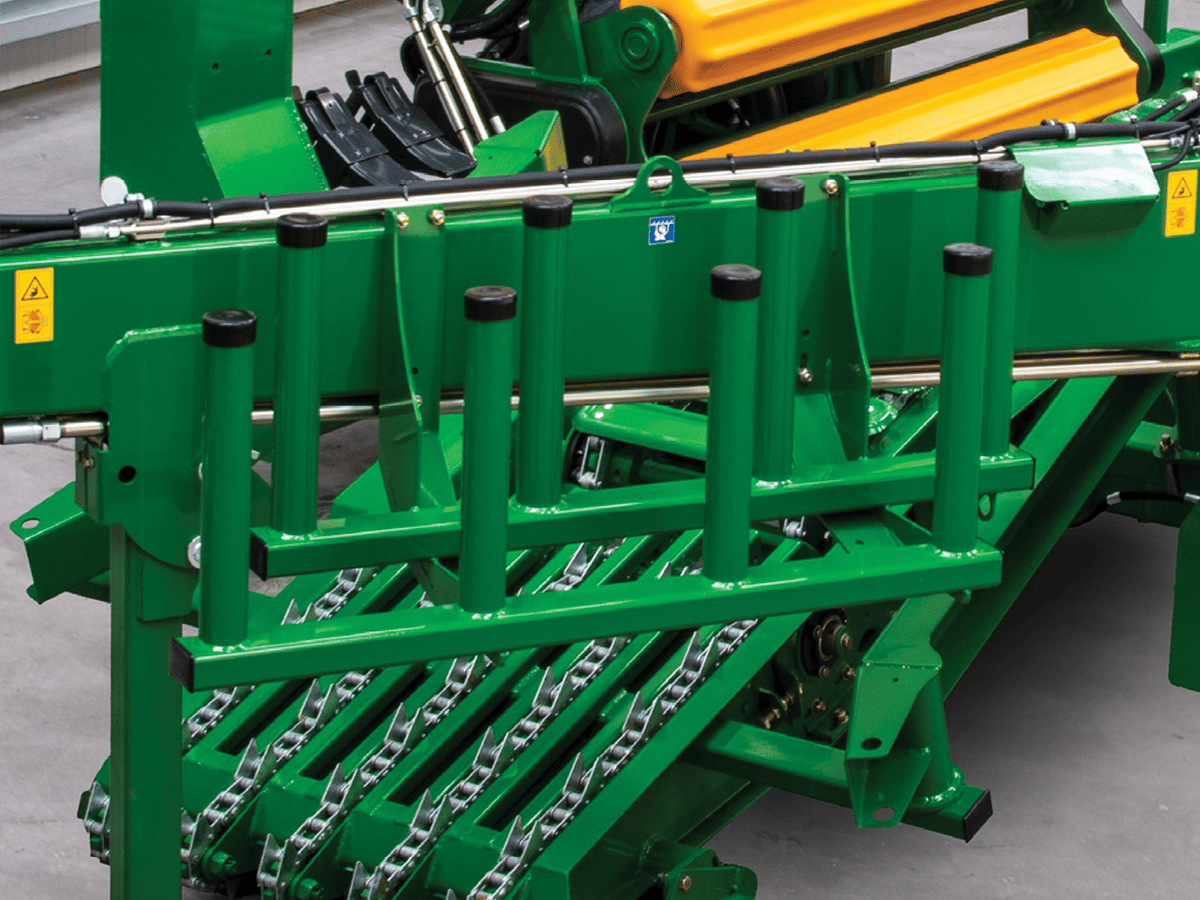

Conveyor Loading

Secondly the front-loading conveyor on the McHale 998 allows for effortless square bale loading. This system allows for 3 bales to be moved together.

Read More

As one bale is being unloaded at the rear of the machine, the next bale is being transported from the front of the machine onto the conveyor. The conveyor can also be used to pick the third bale and carry it as the machine finishes the wrapping process. If the operator wishes to do so, the Auto Load function can be activated which will enable the bale to be automatically loaded onto the conveyor once detected by the sensor. This allows the operator to simply drive the tractor without having to worry about operating the machine.

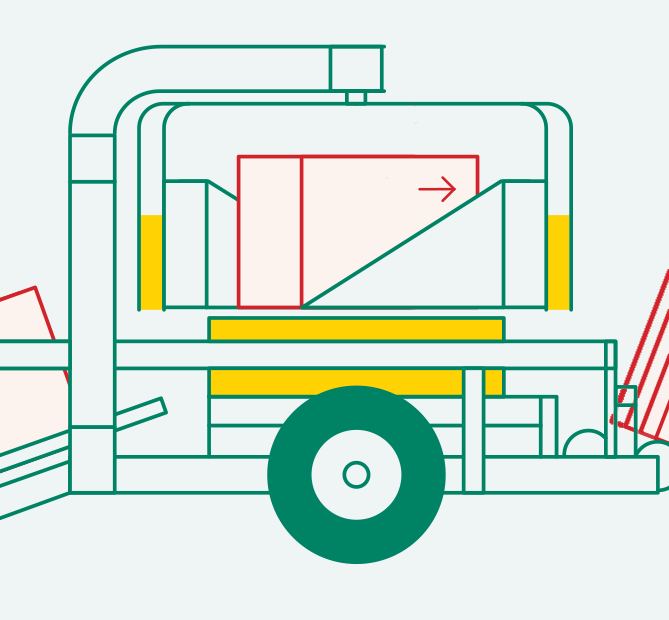

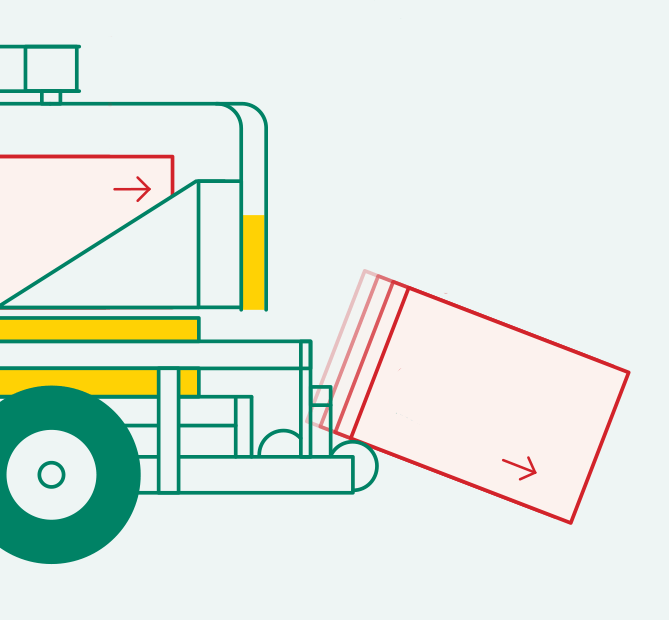

Move three bales at one time

LOAD

Load one square bale onto the front conveyor

WRAP

Move a second square bale from the front conveyor into the wrapping position

UNLOAD

Eject the last wrapped square bale off the back of the wrapper.

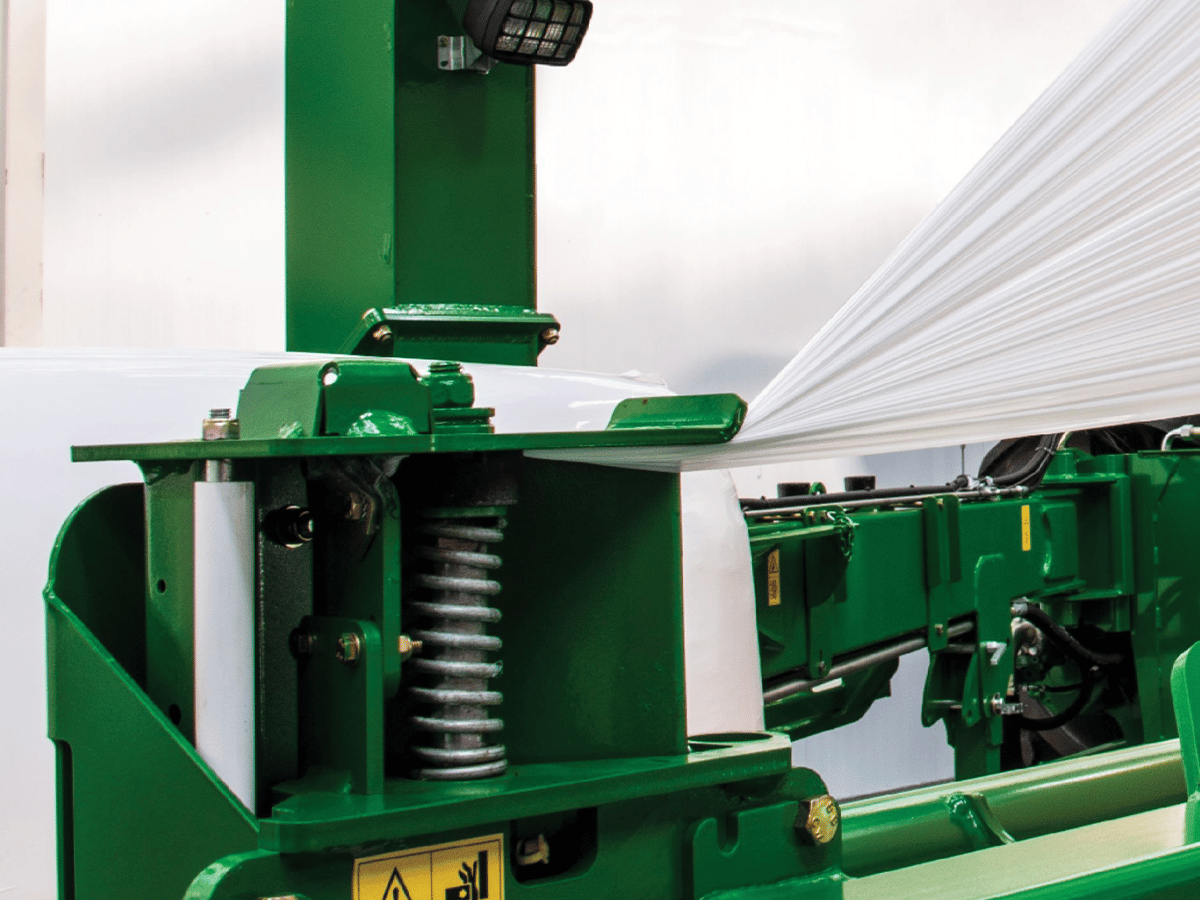

Patented Oscillating Rollers

Read More

This consistently accurate bale movement results in a superior wrap every time as the bale is not relying on gravity. The 4 oscillating rollers are in contact with the bale at all times in order to control bale rotation which ensures the wrap is evenly applied. To ensure wrap is evenly applied, bale rotation is monitored through the use of two potentiometers. These count the corners of the bale and ensure the correct amount of plastic is applied irrespective of the size of the bale.

Patented Roller Angle Measuring & Levelling System

Read More

The patented roller angle measuring and levelling system allows for extra care wrapping. When the extra care program is selected in the control box, bale rotation is slowed down at the corners of the bale and additional plastic is applied which ensures good quality square bales are produced. This careful wrapping program ensures even odd shaped bales can be wrapped at eight predetermined points.

Hydraulic Cut & Hold System

Read More

Once supported the cut and hold gathers the wrapping film to one point where it is cut and held. By gathering the plastic to one point, this reliable system ensures better grip and provides more consistent superior performance, particularly when working in extreme hot or wet conditions.

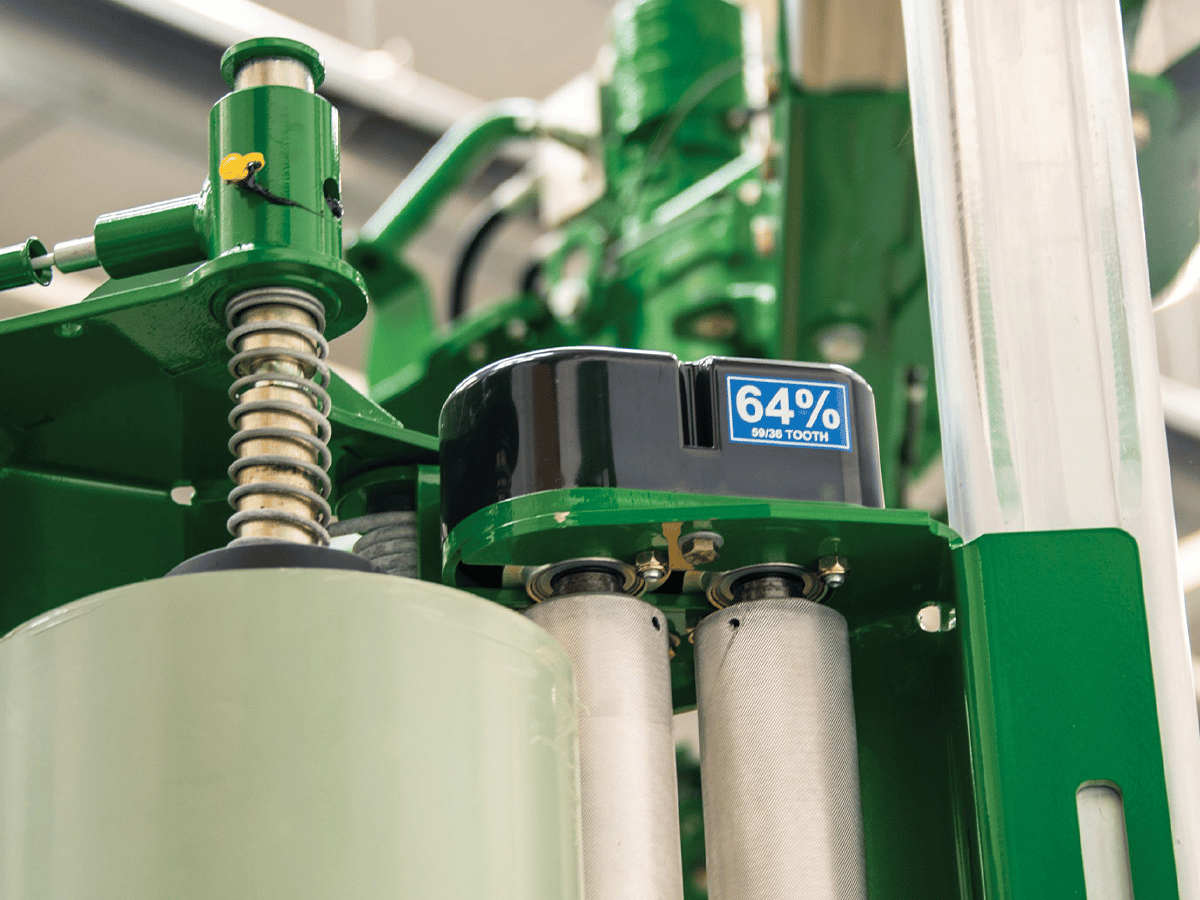

Quick Fit Dispensers

Read More

This gives a more even stretch throughout the roll of film which maximises film usage. The dispenser unit consists of two aluminum rollers, which are geared to each other with robust steel gears of different ratios. If required, the stretch can be adjusted by changing the gears. The dispenser units also feature the McHale user friendly quick fit plastic loading system which simplifies film changing.

Film Break Sensors

The twin satellite dispensers are fitted with film break sensors, which notify the operator through the control console in the tractor cab if one or both dispensers run out of film.

Read More

If one dispenser runs out of film, the machine will continue working and automatically slow bale rotation while also increasing the number of rotations of the wrapping arms to ensure that the bale is wrapped correctly.

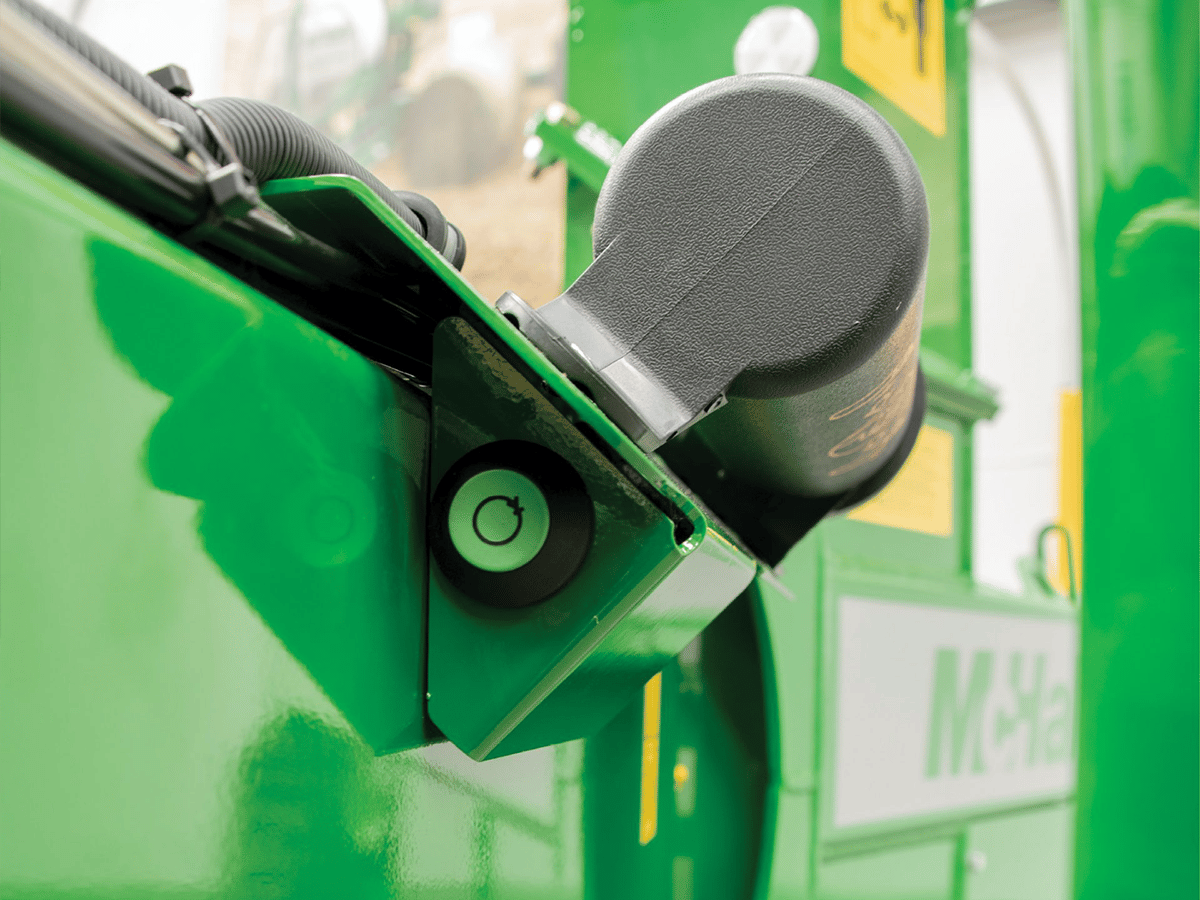

Easy Film Loading

On the McHale 998, the dispenser’s lock and load system simplifies film loading.

Read More

When removing the core of the used roll of plastic the dispenser bobbin locks in place. When a new roll of plastic is in the loading position, it can be locked in place by simply pulling the cord on the dispenser.

Film can be loaded from the left-hand side of the machine with the help of a film replacement loading step.

After loading film on the first dispenser, the operator can push the index button located on the drawbar, and the dispensers will then rotate around and automatically stop at the loading position for the second dispenser. This allows the operator to easily load the second roll of film from the one location.

Easy Film Loading

When removing the core of the used roll of plastic the dispenser bobbin locks in place. When a new roll of plastic is in the loading position, it can be locked in place by simply pulling the cord on the dispenser.

Film can be loaded from the left-hand side of the machine with the help of a film replacement loading step.

After loading film on the first dispenser, the operator can push the index button located on the drawbar, and the dispensers will then rotate around and automatically stop at the loading position for the second dispenser. This allows the operator to easily load the second roll of film from the one location.

Extra Film Storage

The McHale 998 square bale wrapper can carry 12 rolls of film: 2 rolls in the wrapping dispensers and 10 spare rolls in film storage.

Read More

A Film Replacement Loading Step is fitted on all machines to aid the operator when changing a roll of film. This step can be extended out when changing a roll of film and folded back to its original position when the machine is in operation in the field or in transport.

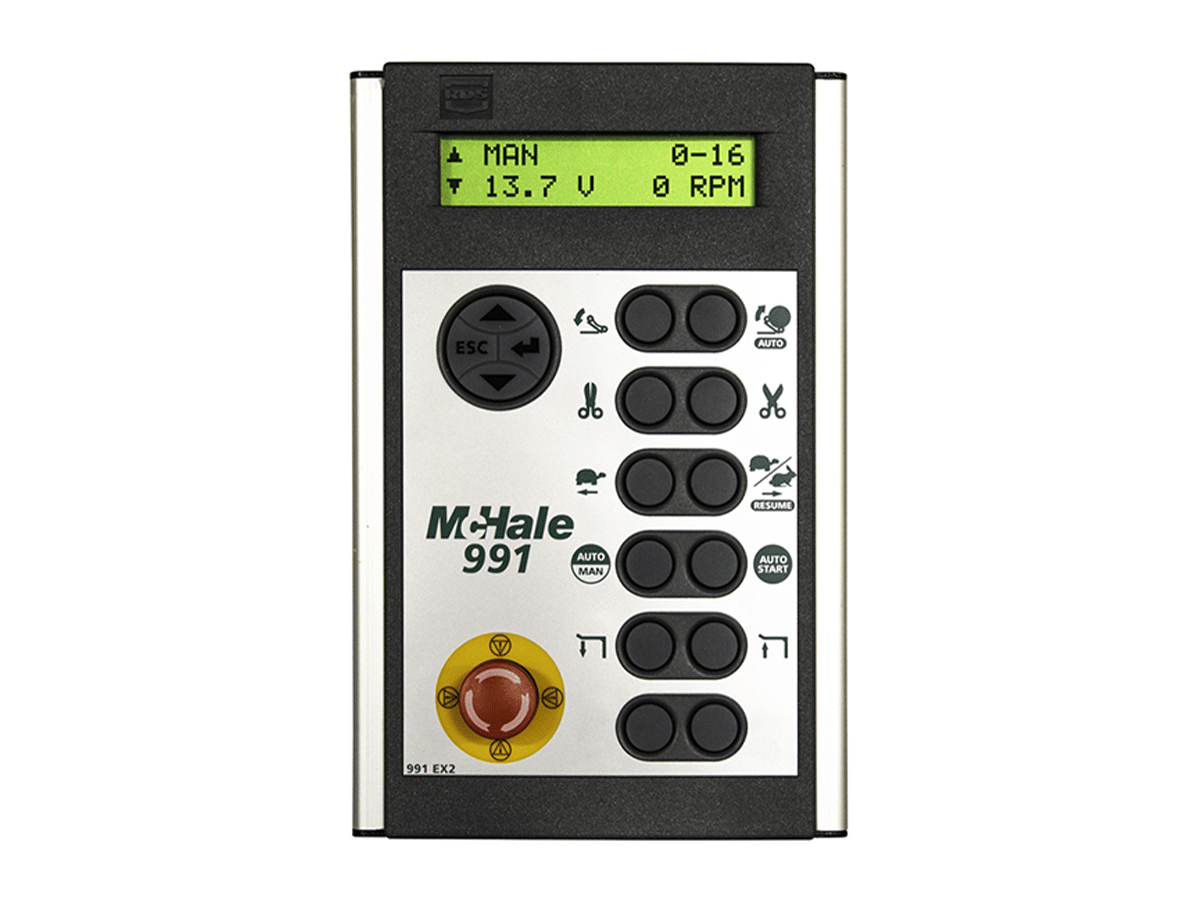

Expert Control Console

Read More

Expert Control Console Functions

Bale Settings & Continuous Automatic Cycle Function

The Expert control console enables the operator to change the bale size and select the desired number of film layers to be applied to the bale.

When set, the continuous automatic cycle function operates the complete cycle from start to finish. This function increases output as when one bale is unloading, the next bale is being transferred from the ground onto the conveyor. Once in position on the wrapping conveyor, the wrapping cycle commences automatically.

Customise the Wrapping Programme

From the control console, it is possible for the operator to select the wrap start position and to customise the wrapping programme. This provides the operator with the ability to apply more plastic at eight points on the surface of the bale and store the customised programme for later jobs which have the same bale size.

Adjustable Maximum Speed & Extra Care Wrapping

An Adjustable Maximum Speed setting is fitted as standard on the McHale 998 High Speed, which allows the operator to set the speed at which they wish to work at from the control console in the tractor cab. This speed can vary from 25rpm to 40rpm depending on the conditions.

The operator can also select extra care wrapping, which makes the McHale 998 square bale wrapper range apply additional plastic on the corners of the bale which is particularly beneficial to rectangular shaped bales.

Wired Handpiece Control

Options

Read More

998 High Speed Optional Extras

Radio Remote Control Kit

Should you wish to use the McHale 998 or 998 High Speed bale wrapper for static wrapping, a new radio remote-control kit is available. This allows the machine to be efficiently used as a static machine for wrapping round or square bales. An operator can load the bale wrapper using a loader and easily activate an automatic cycle by using the radio remote control.

Static Wrapping Unloading Conveyor

The McHale 998 and 998 High Speed is available with an optional rear unloading conveyor. This unloading conveyor can be used when static wrapping to allow the careful unloading of a bale from the wrapper. To avoid damage to the plastic, the bale is unloaded from the wrapper onto the conveyor where it is held until it is collected by the loader and placed in the stack. This ensures the wrapped bale has no contact with the ground. When the wrapping job is complete, the unloading conveyor is neatly folded up for transport.

Air Brakes

All machines in the McHale 998 square bale wrapper range come fitted with hydraulic brakes as standard but can be specified with air brakes as an optional extra.