C490-Trailed

C490 Trailed Silage Feeder and Straw Blower

The McHale C490 Trailed Silage Feeder and Straw Blower has a higher capacity to carry and blow or feed out three 5ft round bales of hay, straw, silage or haylage

Overview

The extra capacity of the McHale C490 allows farmers to increase their output when bedding or feeding, especially if they may be using the machine on another farm which is some distance away from the main farm. The McHale C490 is available with an optional linkage drawbar which allows the machine greater access to tight sheds with narrow entrances.

Twin Speed Gearbox

A key feature on the C4 range is its twin speed independent gearbox, which allows the operator to easily adjust from 280 rpm for feeding silage or hay up to 540 rpm for using the machine to distribute straw for bedding.

Feeding

The McHale C4 range of machines are ideal machines for feeding silage and hay, the twin speed gearbox allows silage and hay to be distributed exactly where it is desired. The speed of the conveyor is proportionally controlled allowing the operator to adjust feeding speed depending on the material density and composition.

Bedding

The McHale C4 range of machines can be used to distribute bedding material quickly and efficiently leaving a thick aerated bed of straw. In difficult to access bedding areas, the chute on the McHale C4 range can pass through 300 degrees for ease of bedding. Straw can be blown up to 18m.

Built To Last

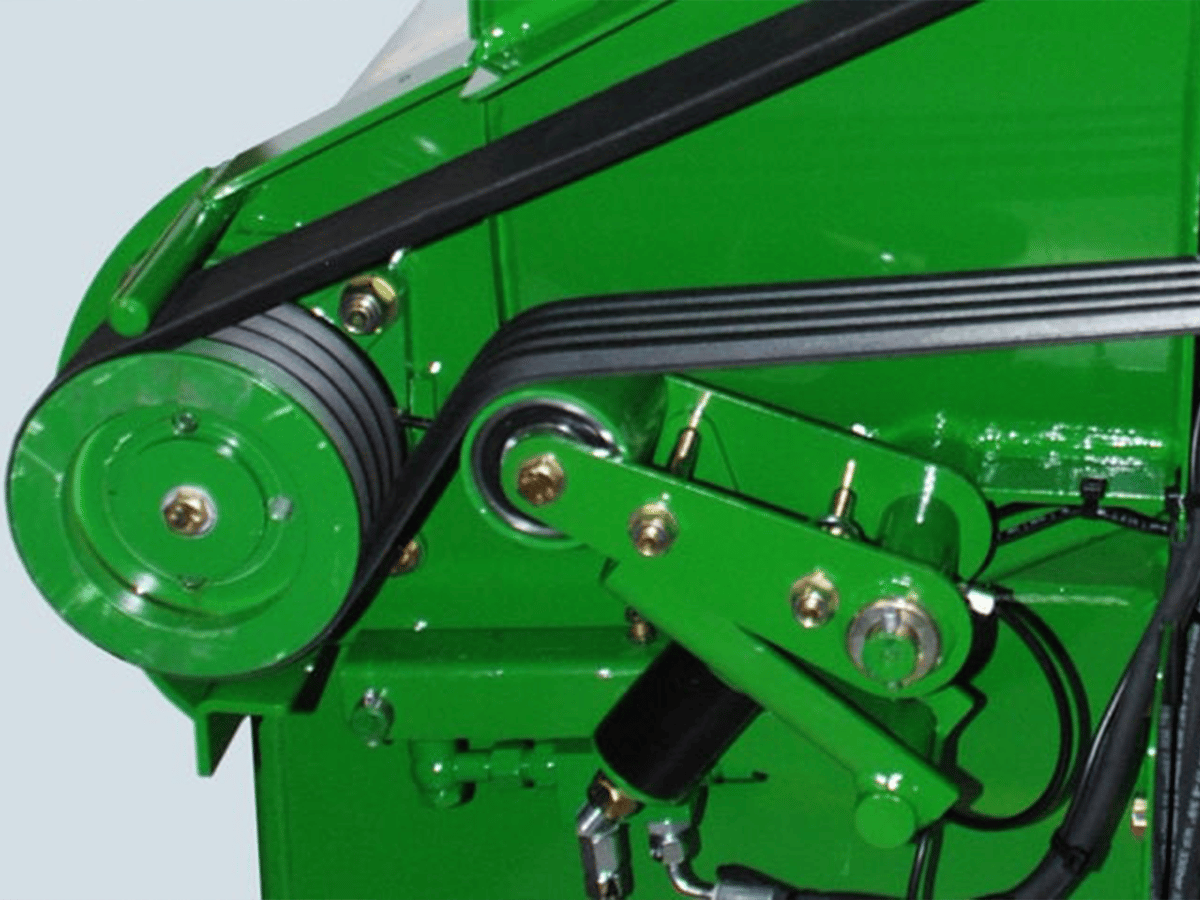

Twin Speed Gearbox

All machines in the McHale C4 Silage Feeder & Straw Blower range are fitted with a twin speed gearbox which controls the speed at which the flywheel distributes the material.

Read More

There are two speeds at which to choose from depending on the task at hand; 280 rpm and 540 rpm.

280 rpm

At 280 rpm, which is represented by the “Tortoise”, the flywheel operates at a slower speed for feeding out fodder by deflecting it onto the distribution tray on the side of the machine.

540 rpm

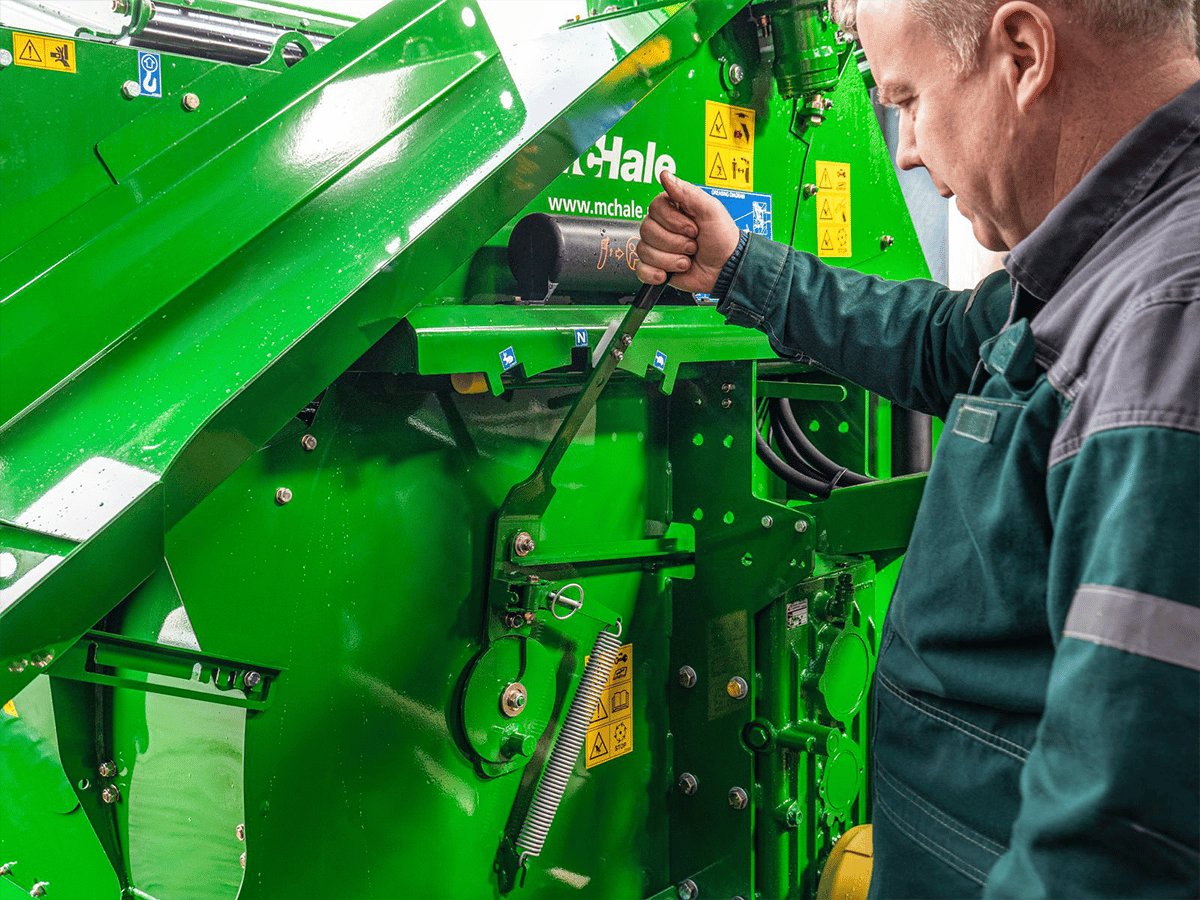

When distributing straw for bedding, 540 rpm is selected by moving the handle on the gearbox to the position with the “Hare” symbol to provide a high speed rotation of the flywheel to achieve a maximum blow distance.

Floor Conveyor

The floor conveyor on the McHale C4 Silage Feeder & Straw Blower Range, consists of a hydraulically driven chain and slat conveyor. The speed can be adjusted and the conveyor can be reversed from the tractor cab.

Heavy duty galvanised slats are mounted on 11mm high tensile chains using “U” bolts for easy maintenance. Heavy duty, wear resistant rollers and nylon strips reduce wear to a minimum. The conveyor formation has been designed to ensure consistent and even feed to the rotor.

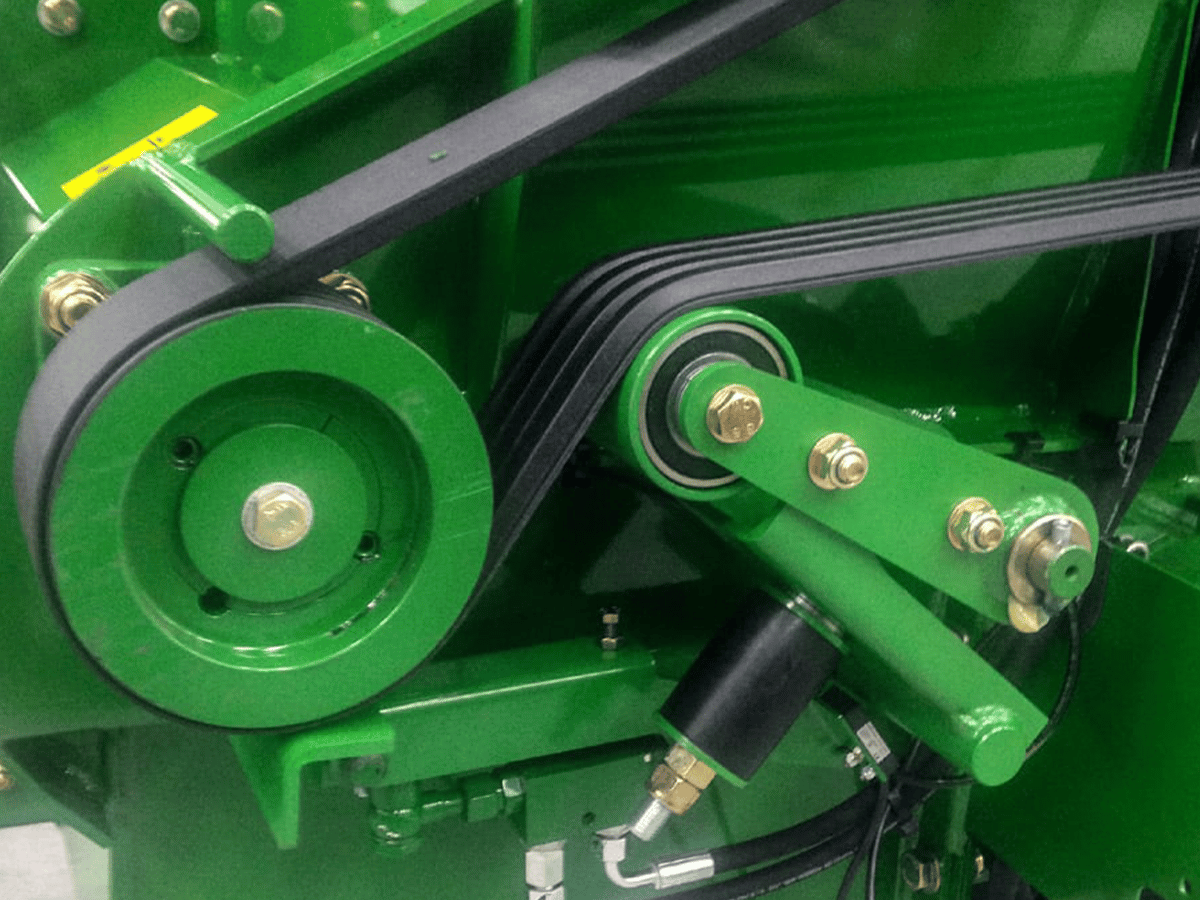

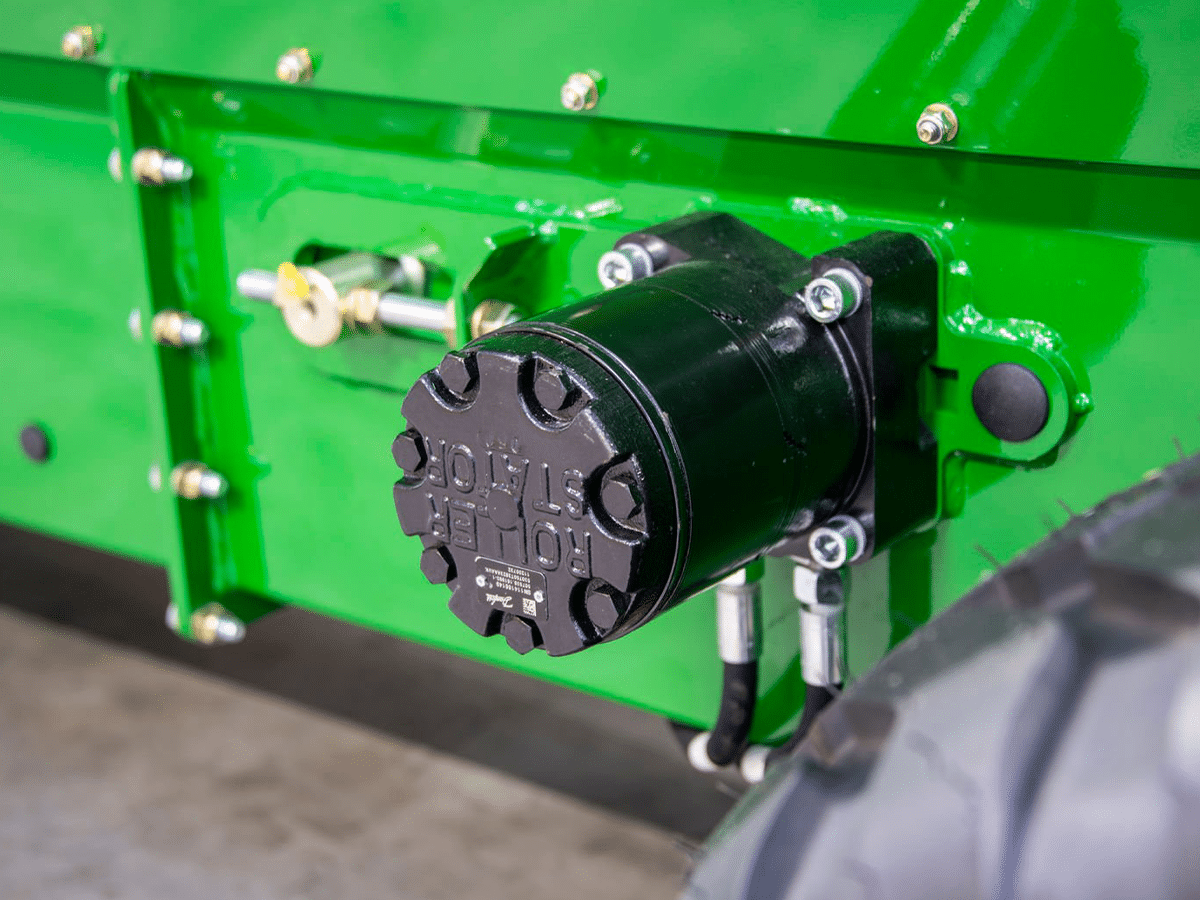

Rotor with Hydraulically Activated High Torque Belt Drive

Read More

The blades are mounted at an angle on the discs and pass through a fixed comb to ensure the material is cut and fed into the flywheel evenly. This design minimises crop build up on the rotor. The High Torque Belt Drive, which drives the feed rotor, can be hydraulically engaged or disengaged from the tractor cab. This drive system allows the feed rotor to run independently of the flywheel, which enables the operator to bring the flywheel up to full speed before starting the feed rotor.

This gives a number of advantages, namely:

- The flywheel (straw blowing turbine) can be at full rpm before the rotor starts to feed.

- Horsepower requirements are reduced.

- It ensures that the machine is less likely to block on start up

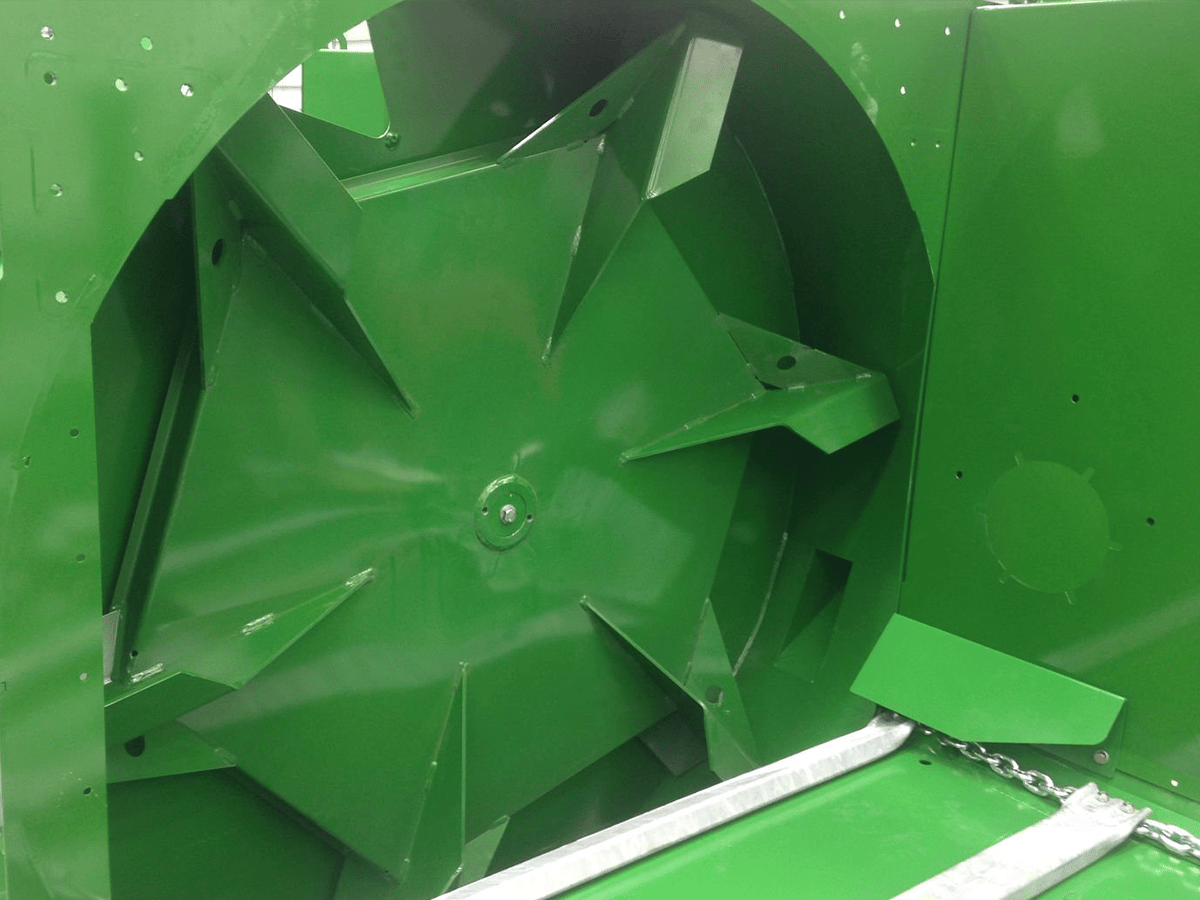

Flywheel (Straw Blowing Turbine)

The 1.57m diameter flywheel on the McHale C4 Silage Feeder & Straw Blower range is fitted with 6 blowing paddles, which provides a powerful blow for the efficient distribution of material.

The flywheel housing is positioned below the conveyor, this design ensures that any loose material which falls into the flywheel housing is blown out. The flywheel rotates below the conveyor which improves the delivery of full length fodder for feeding or bedding and ensures that no fodder remains in the machine after use.

Control Console

The McHale C4 Silage Feeding and Straw Blowing Range is controlled via an Expert control console allowing the operator to control machine operation from the tractor cab.

Read More

This user friendly control console provides the operator with access to all the functions of the machine without ever having to leave the comfort of the tractor seat. The following actions can be operated via the control console:

Blowing & Feeding Chute

Read More

This Blowing & Feeding Chute gives a number of advantages, namely:

- Straw can be blown 18m on the right hand side.

- For difficult to access bedding areas the 300° chute can blow straw up to 13m to the left hand side of the machine.

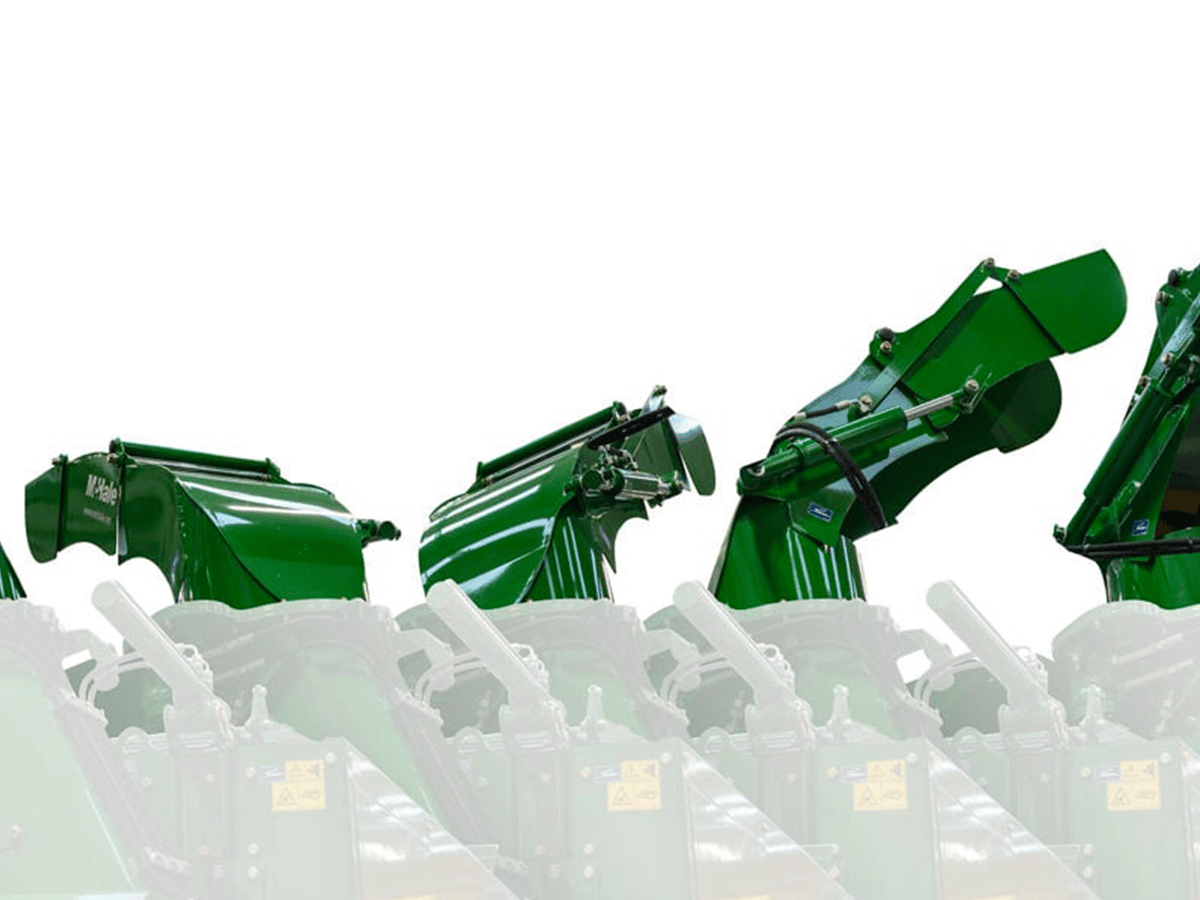

300˚ Three Stage Chute

The chute on the McHale C4 range of machines can pass through 300° for ease of bedding in a building with narrow passages or in confined spaces. The 3 stage chute is designed to move through an arc which means crop can pass through the chute easily and the chute does not reduce blow distances.

Chute Joystick

The chute is joystick controlled, allowing the operator to adjust the chute height and the shoot direction easily from the control console in the tractor cab.

The chute can be rotated 300°, which allows material to be spread on the left, right and behind the machine. The chute may also be lowered to blow material on to the feeding slide for better control when distributing feed along a barrier.

Power & Flexibility

Independent Floor Conveyor

As the floor conveyor works independently from the rotor, this ensures that fodder can be reversed away from the rotor without disengaging the rotor.

Bale Loading

The tailgate on the machine can be used to load a bale without the need for a second tractor.

The cupped tailgate design ensures a bale is held in the dip in the tailgate, while the twine or net is being removed. The ram mounting points on the tailgate ensure that maximum lifting power can be achieved so that the heaviest of bales can be handled.

Maximum Output

The McHale C4 Silage Feeder & Straw Blower range of machines are designed to allow the rotor work independently from the flywheel. This allows the flywheel to be at full RPM before any fodder material is fed into the rotor.

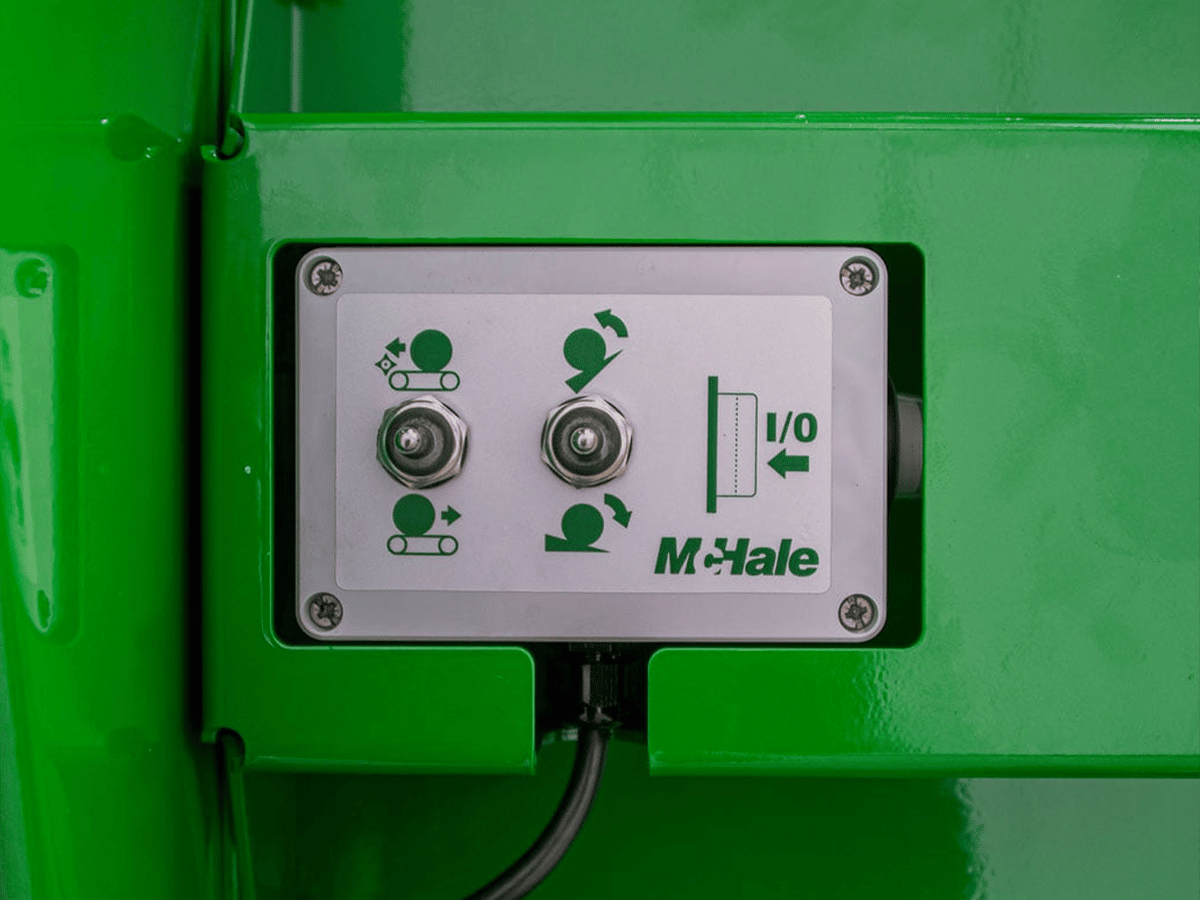

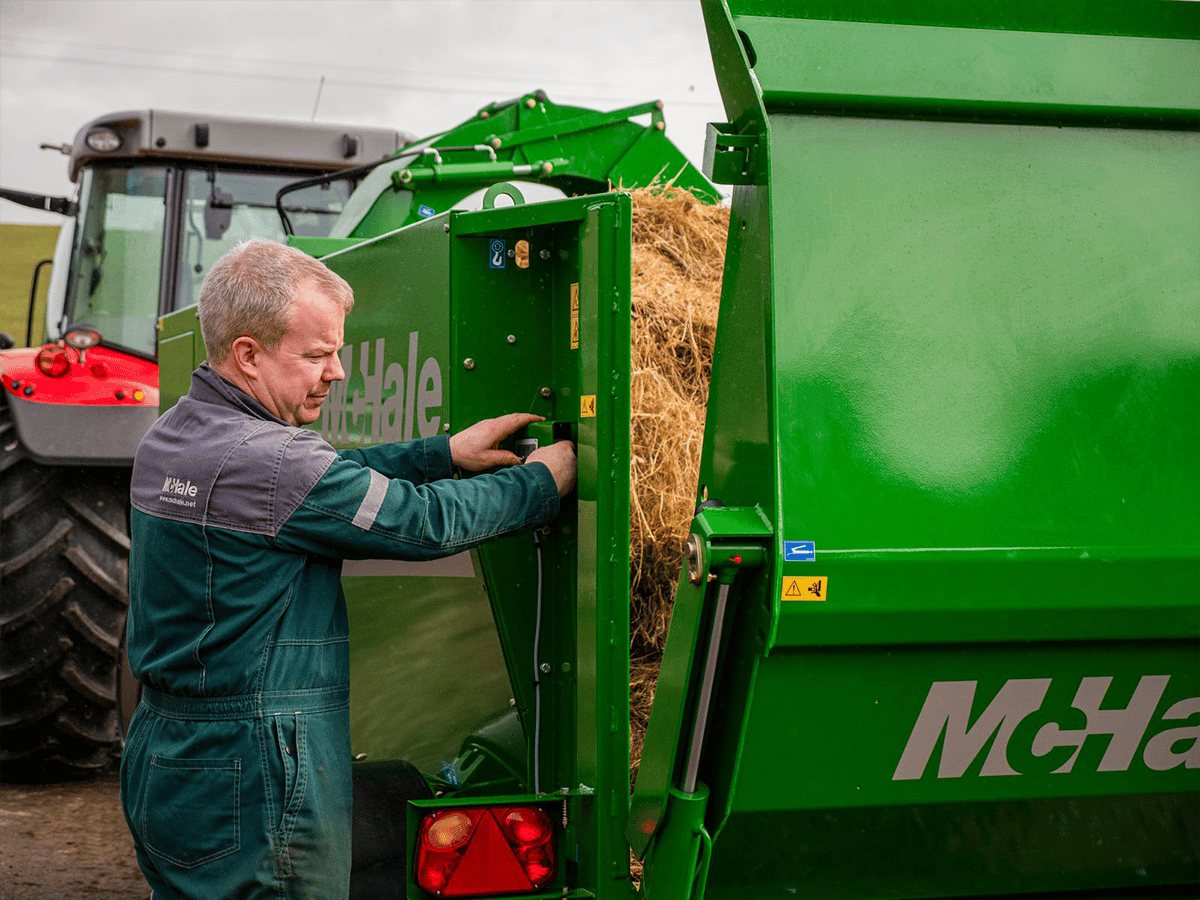

External Loading Control

An external loading control comes fitted as standard which will allow for the conveyor floor and the tailgate to be operated when removing the netting or wrap whilst loading a bale.

The tailgate and conveyor alignment on the machine body take the largest size square bales without the need for extensions to the tailgate

Safety First

To prevent accidental operation of the controls, a safety button on the side of the External Loading Control must be pressed while operating loading functions at the rear of the machine.

The tailgate and conveyor alignment on the machine body take the largest size square bales without the need for extensions to the tailgate